Recently, the 10th CPRJ Plastic Packaging Technology Forum and Exhibition hosted by Elegant Group was held in Shanghai.

Johnson & Johnson (China) Co., LTD., Henkel, Kmart, Uni-One, Kraft Heinz, Danone, Liby, Energon Group Guangdong Energon Plastic Manufacturing Co., LTD., and other enterprises from retail, food, daily necessities, packaging, equipment manufacturing and other industries attended the conference. Sustainable development technology, packaging innovation, functional new packaging, intelligent production program and other issues were discussed.

Lecture given efficient packaging molding solutions for the new lifestyle

Zhang Jialiang, Technical Director of Guangdong Lijin Plastic Intelligent Manufacturing Co., LTD., Lijin Group, delivered a keynote speech and shared with the participants the efficient production solutions of thin-wall packaging products under the O2O new lifestyle reform.

Under the new way of life, the pace of life is accelerated, the cooking time is reduced, the demand for packaging is large, the packaging is required to be safe, environmental protection, clean, high temperature resistant, suitable for low temperature refrigeration and quick-freezing. LENA series direct pressure injection molding machine and ELETTRICA series all-electric injection molding machine, newly designed and developed by Lijin Group, accurately match the production requirements of packaging products.

LKIMM LENA series direct pressure injection molding machine adopts modular design and mold locking structure of direct press. Linear guide rail is adopted for sliding template. Single cylinder nitrogen injection glue is equipped with high precision closed-loop servo valve. The plasticizing system is optimized for the packaging industry. It adopts special screw with high mixing and is equipped with stable electric melting glue system. The shooting speed can be as high as 500MM/s, which can efficiently produce thin-wall packaging products such as fast food boxes, yogurt boxes, ice cream boxes, disposable tableware and so on.

ELETTRICA series all-electric injection molding machine adopts all-electric mold locking mechanism, all-electric shooting platform, professional material tube group, high-precision intelligent mold protection system and highly integrated automatic lubrication system. Mode-locking structure adopts linear guide rail, low energy consumption, high precision and smooth operation. The contact parts of the product are made of stainless steel, and the protective cover of the stainless steel barrel is treated with anti-sticky dust. No contact between the tie rod and the moving mold, to avoid secondary pollution. It is suitable for efficient and clean production of all plastic pump and after consumption recycled plastic (PCR) products.

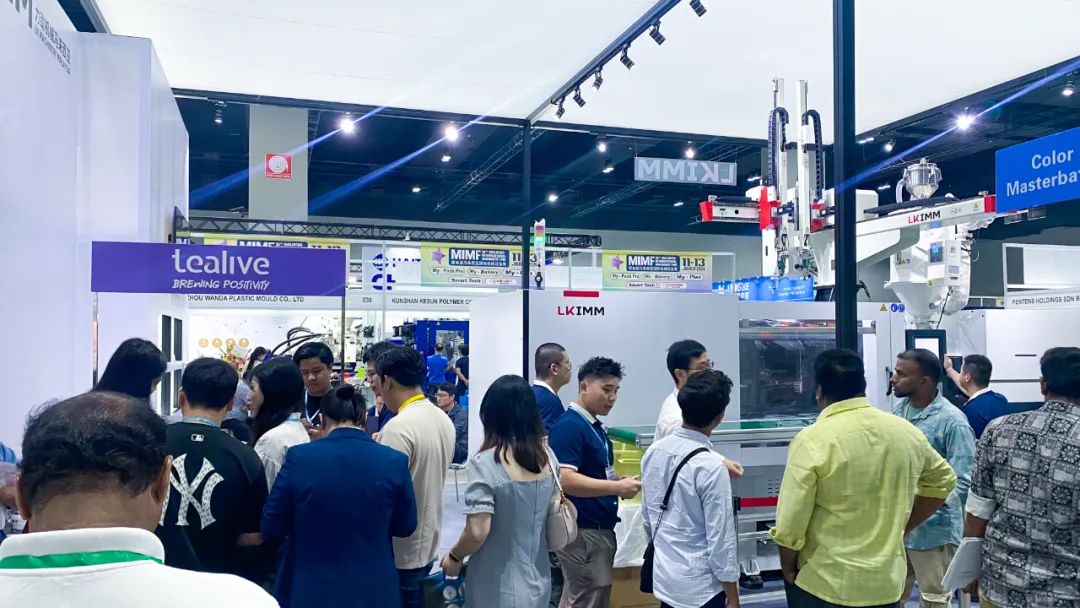

Show direct injection machine with Force LENA series

Lishen staff introduced Lishen LENA series direct pressure injection molding machine and answered the audience's consultation.

At present, the plastic packaging industry is accelerating the transformation to the circular economy model, which plays an important role in ensuring the realization of the "double carbon" goal and realizing the multiple benefits of environment, economy and emission reduction.

Lijin Group is committed to developing advanced, environmentally friendly, safe and green packaging products production solutions, focusing on the design of top technical solutions of recycling production system of plastic enterprises, to meet the needs of enterprise development and green consumer market, and promote the development of recycling economy of plastic industry.