LK Injection Molding Machine Co., Ltd. (LKIMM, previously known as "Zhongshan L.K. Machinery Co., Ltd.") is the holding subsidiary company of LK Technology Holdings Limited. After rapid development for more than 20 years of R&D, manufacture and sales experience, LKIMM has developed six series of products: FORZA two-platen machine , POTENZA servo energy-saving, ELETTRICA all-electric machine, LENA direct-hydraulic, and VARIA multi-component series. LKIMM continues to break through the cutting-edge technology of injection molding machine development, promotes the intelligent development of products and services, and continuously improves market competitiveness.

About Company

Welcome to LKIMM

LK was founded in 1979, LK Technology Holdings Limited, was established in 2004, and became the listed company of the Stock Exchange of Hong Kong in 2006. LK Group has 12 production bases including LK Injection Molding Machine Co., Ltd. and Ningbo LK Injection Molding Machine Co., Ltd. LK has more than 60 service and technical centers. The sales and services cover China, Vietnam, Japan, India, Southeast Asia, North America, Europe and other countries and regions. After more than 40 years of development, LK Group has developed into the top five injection molding machine manufacturers in China, the world's most well-known die-casting machine manufacturer and the most solution-oriented CNC machining center manufacturer.

Production Base

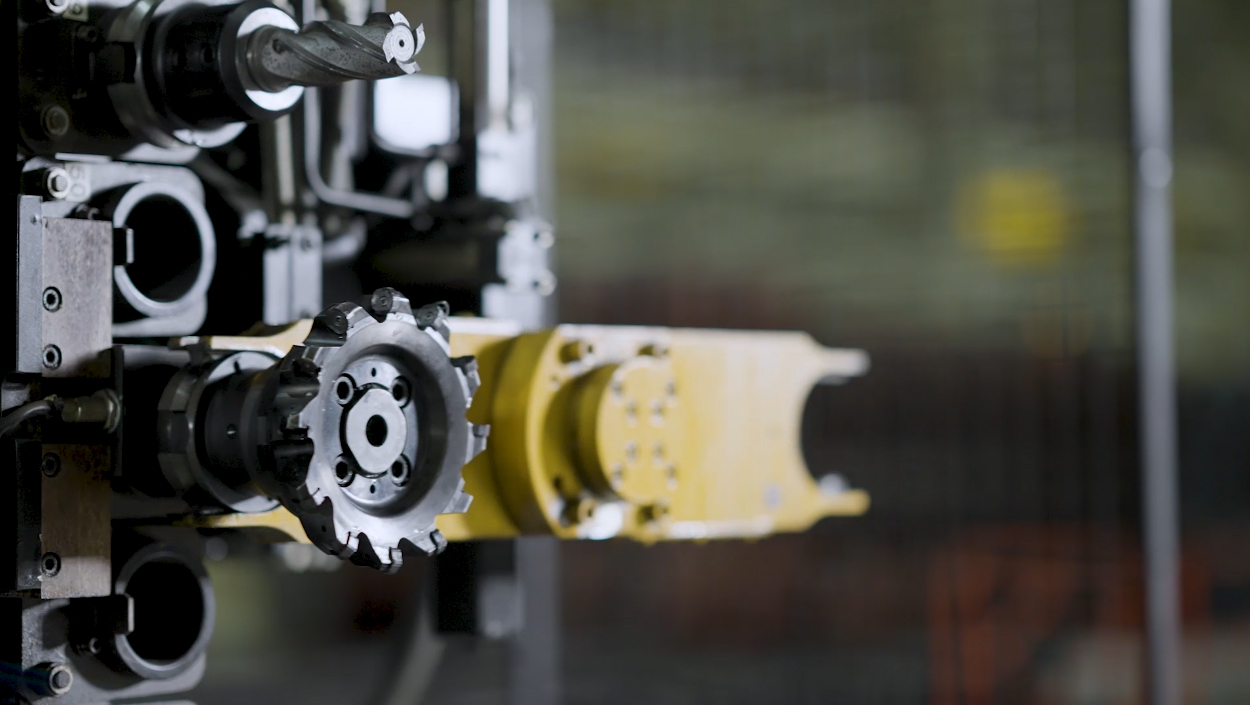

Plastic Injection Molding Machines

-

1994YearsLocated in Zhongshan, Guangdong, with a total area of more than 90,000 square meters, sales cover more than 60 countries and regions.

-

Founded in 2002, Ningbo LK Injection Molding Machine Co., Ltd.is located in Ningbo economic and technological development zone, founded in 2002, with a total investment of 600 million CNY, covering an area of 100,000 square meters. Specialize in manufacture servo hydraulic series Potenza, two-plate series Forza, Multi-component series, thin-wall high-speed series and various industries customized special injection molding machine. The maximum clamping force of two-plate injection molding machine is 7000 tons, and it is an important manufacturer of injection molding machine in China.

2002YearsLocated in Eastern China, with a total area of more than 100,000 sqm

Vision & Mission

Shape the future, shape the world

-

01LK, strives for your success

-

02Shape the future, shape the world

-

03Cares about customers needs

-

04Nurtures talents and team spirit