On October 19, the K2022 International Plastics and Rubber Exhibition was officially opened in Dusseldorf, Germany.

In the era of double carbon economy and intelligent manufacturing, Lijin Plastic Machine continues to upgrade around the "youth experience", further enhance product value and service experience, and provide users with one-stop injection molding solutions. The newly designed "Supreme" series Lijin Injection Molding machine officially debuted in K2022.

At booth 13B45, two upgraded products of the "Supreme" series of injection molding machines -- Elettrica all-electric injection molding machine and Forza two-plate injection molding machine were displayed for the first time.

Based on LK Injection Molding Machine, LKIMM has formed a new LOGO for continuous expansion and pursuit of excellence. With a younger attitude, fully enter the international market. With a new image, younger, more intelligent, more environmentally friendly concept, kernel upgrade, to bring better solutions for users.

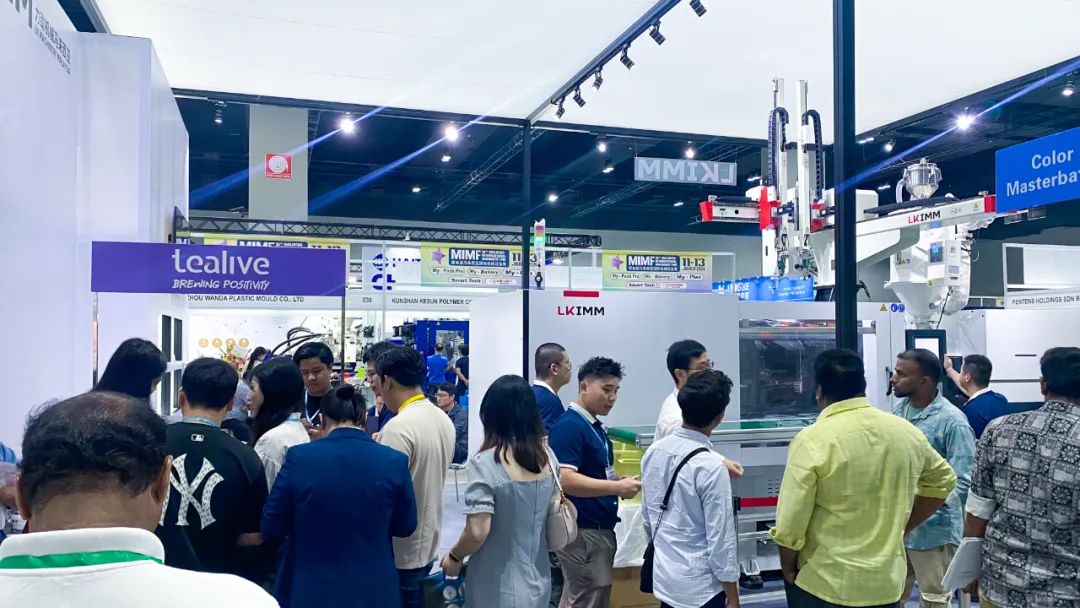

On the opening day of K2022, visitors from Germany, France, Austria, Italy and other European countries and regions visited the exhibition booth of Lishen Plastic Machines to visit and learn about Lishen "Supreme" series injection plastic machines.

Elettrica all electric injection molding machine new upgrade

The latest family language of LKIMM is adopted to create "supreme" minimalist design. Precision, efficient, clean, safe, intelligent, mechanical safety, electrical safety, program safety three modes of all-round protection, to meet the needs of intelligent manufacturing in medical, packaging, 3C electronics and other industries.

It is equipped with a 15-inch integrated display and control screen, Intel X86 processor, and supports the flexible process control system and OPC-UA protocol interface. The mode-locking movement adopts linear guide rail, equipped with high response servo motor and non-contact pull rod. The speed of opening and closing mold is up to 700mm/s, and the control precision of mold locking position and melting position is up to ±0.01mm, which realizes the combination of high precision and high efficiency.

Forza two plate injection molding machine comprehensive upgrade

Absorbing the latest design of the "supreme" series injection molding machine, the overall appearance of the three-dimensional sheet metal structure, with CMF process. It has realized four major upgrades: increasing servo power, increasing inner distance of Gorin column, configuring proportional valve of opening and locking mold and optimizing hydraulic oil circuit. Single cylinder injection with high precision and high rate of fire is adopted in the shooting platform. Linear guide rail is adopted in the shooting platform and mode-locking part. The whole machine is more responsive and energy-saving effect is more significant. It is widely used in the efficient production of deep cavity products, composite materials, multi-component molding and highlighter plastic products. After more than 40 years of development, Lijin plastic machine has experienced several iterations of upgrading. Every upgrade is an innovative change. In the injection molding industry 4.0 accelerated development, Lijin plastic machine is committed to provide enterprises with green, intelligent, sustainable production solutions.

K2022 will last until October 26th. Stay tuned for our report. The booth number of Lijin is 13B45!